CULTIVATION

|

| |

| 1. VIS ON LAND Plough |

| |

|

|

The new semi-mounted reversible VIS on LAND S plough is adapted to traditional furrow ploughing and to work on uncultivated soil path. Models 5+1/6+1/7+1 are available (“+1” means that the last plough body can be added or dismounted). The ploughs have rigid frames with a bar cross-section of 160x160 mm. The distance between the bodies is up to 105 cm, which minimizes the risk of clogging up with harvest residues. The ploughing width can be gradually adjusted, with 37/43/49/55 cm per body. In the case of the VIS on LAND S 7+1 plough, it means it can reverse 4.4 metres strip of soil in one pass.

The ploughs are offered with two types of protection: bolt-protection (shear-bolt) and a spring-leaves Non-Stop type with a letter S at the end of the model name (7-leaf spring). LONG bodies with trash-boards are used as standard equipment, but optionally there can be BIG LONG bodies or slatted openwork LONG bodies with higher and longer mouldboard assembled, for work at a depth of more than 32 cm.

VIS on LAND S plough is a novelty of UNIA brand presented for the first time at the Agro-Show 2018 trade fair.

|

| |

|

|

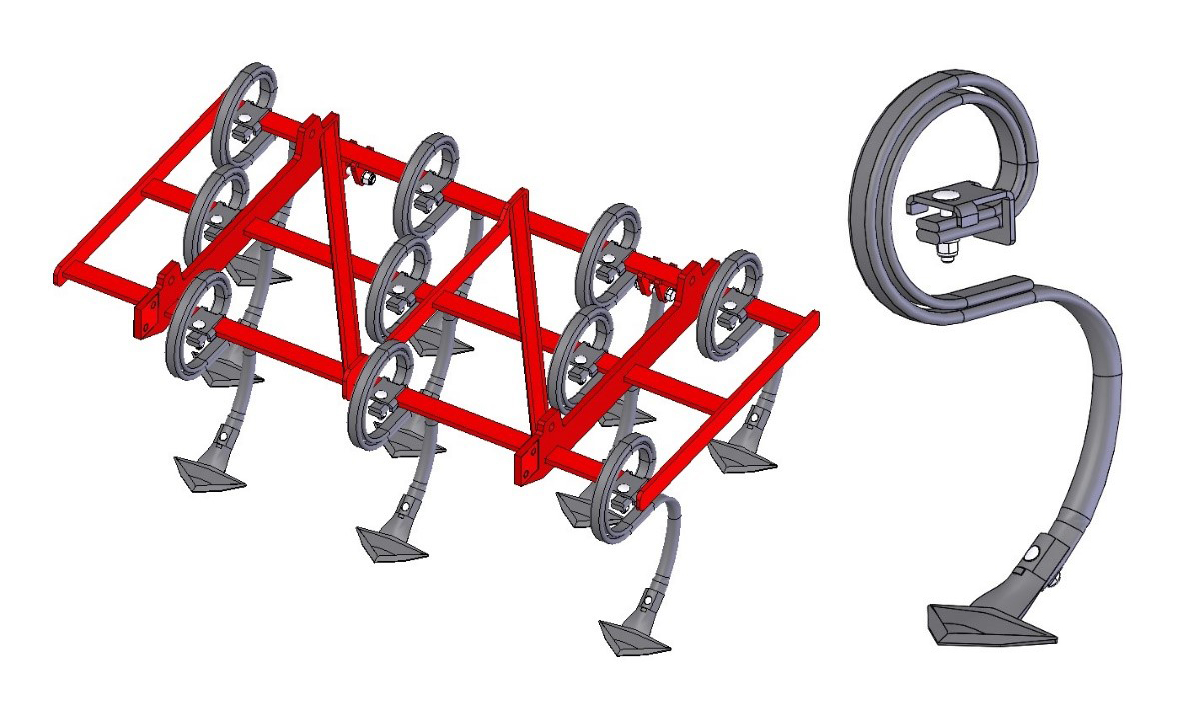

| 2. Pre-seeding tine cultivator ATLAS II |

| |

|

|

|

|

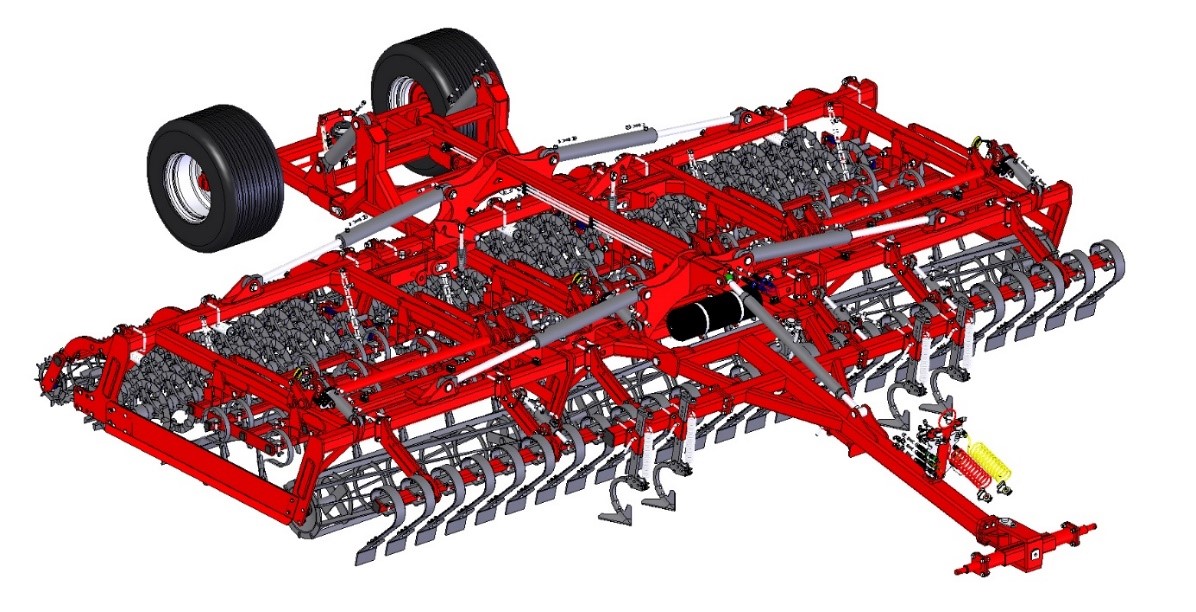

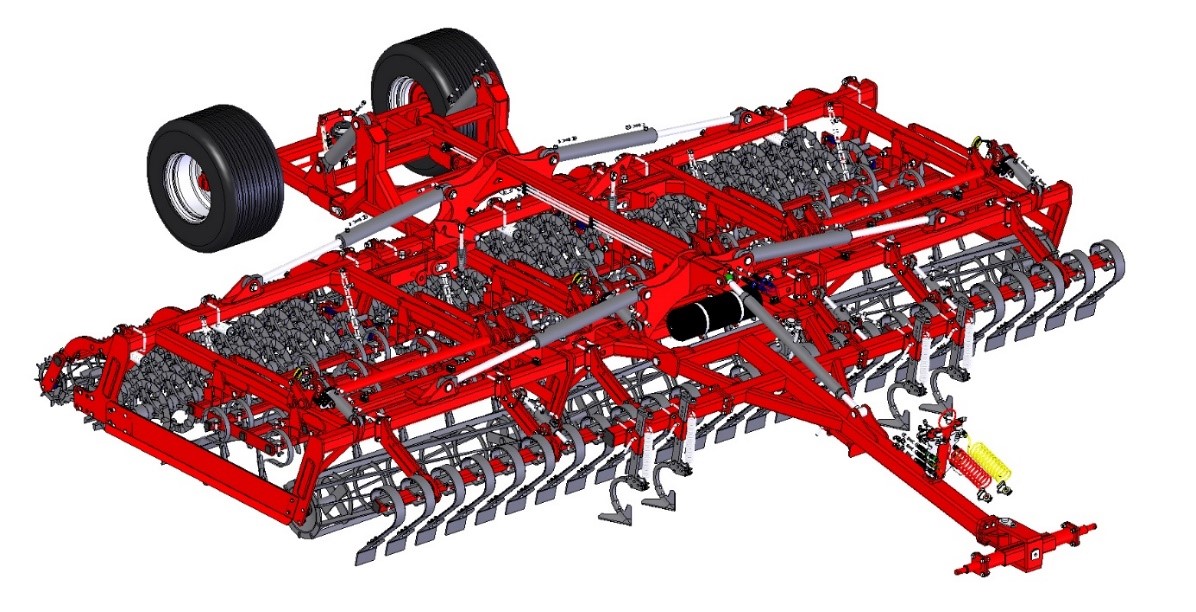

The completely new line of semi-mounted pre-seeding tine cultivators ATLAS II is available with working widths of 4/5/6/8/10 metres. In standard version unit is equipped with such working elements as: track openers with point adjustable working depth, front skid, front string roller with a diameter of 400 mm, 2-row section of SX tines with 260 mm undercutting width and covering skid. New to the scope of equipment are double string cultivating rollers with a diameter of 400/400 mm. The final levelling element is a toothed skid with spring clamping. The unit has a semi-mounted construction. It is based on a chassis with tyre dimension of 480/45-17 and can be folded hydraulically for transport. The integrated hydraulic lock secures the machine during transport.

ATLAS II cultivators can be optionally equipped with e.g. alternating cultivation Crosskill rollers or hydraulic depth adjustment.

|

| |

|

|

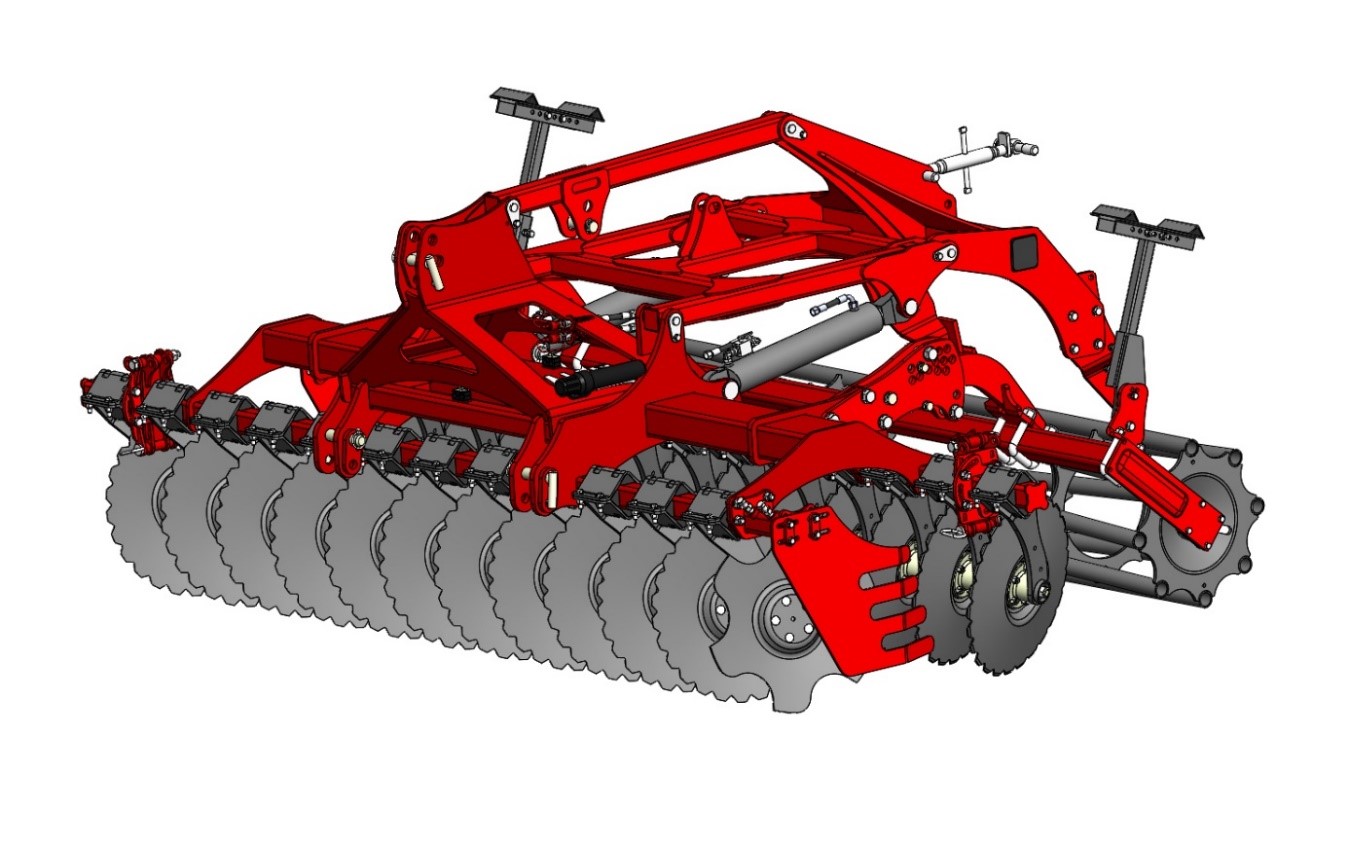

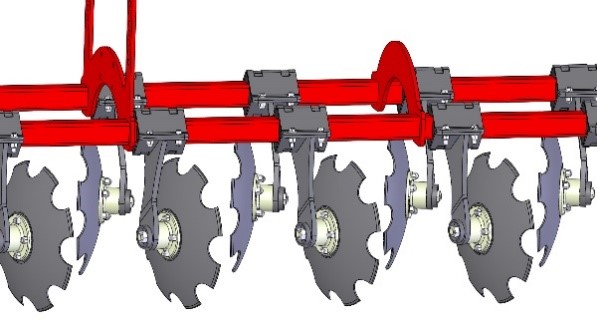

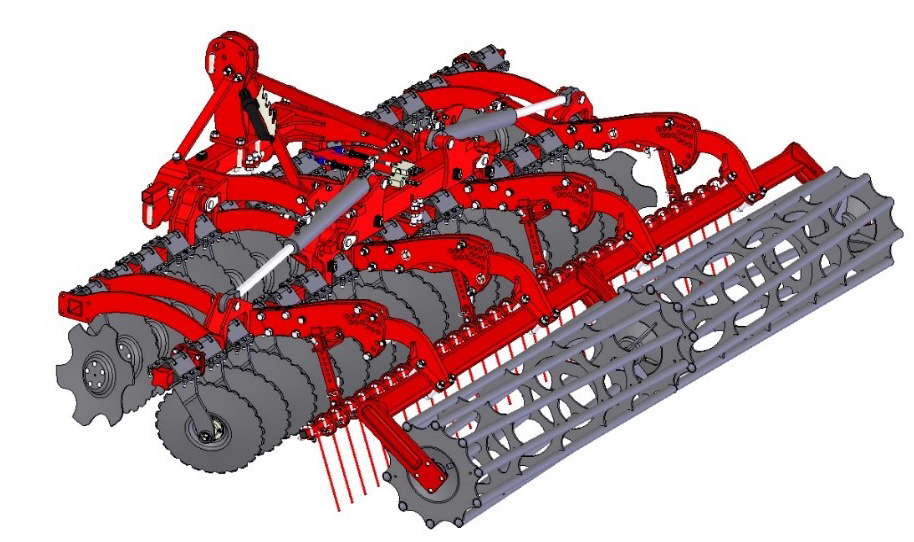

| 3. ARES XLH 4 – new hydraulically folded frame design |

| |

|

|

|

Modernization of ARES unit allowed to modify the design of the main frame. Up to now, the sections were folded to transport by means of one hydraulic cylinder. The new solution introduces two hydraulic cylinders used for folding and unfolding of the unit. Each section is folded with its own hydraulic cylinder.

Another novelty is the introduction of the replaceable maintenance free bearings assemblies, characterised by compact design and simplicity of replacement of the bearing sets. This modification will reduce the unit operation costs. |

| |

|

|

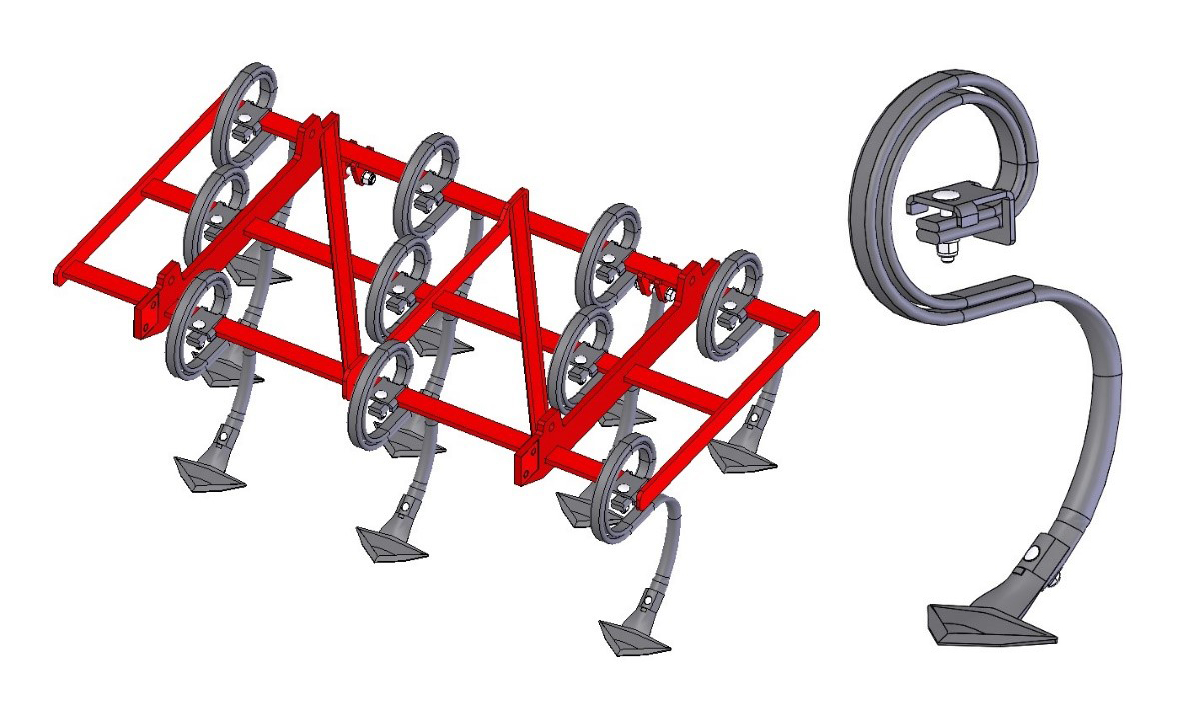

| 4. Modular cultivator MAX |

| |

|

|

|

The name of the new modular cultivator unit indicates that it can be used with a wide variety of configurations of working elements and cultivation rollers. This allows to be adapted to different soil conditions.

MAX unit is suitable for all kinds of soil, especially in medium and heavy conditions. Its advantage is field surface copying system, i.e. precise adjustment of working fields to the base surface. MAX units have separate suspension systems, which allow the working sections to be freely positioned to suit the field's unevenness. MAX is available in three versions:

- MAX: front string roller with a diameter of 390 mm, 4-row section of SV (45x10 mm) tines with a coulter and a double string cultivating roller 320mm/280 mm

- MAX SC: first two elements (roller and section of tines) are the same, but the configuration of the rear rollers is changed to Crosskill /String with a diameter of 320/280 mm

- MAX CC: with Crosskill /Crosskill roller configuration 320/320 mm

As optional equipment there are available:

- cultivation section with a 2-row section of SX tines with a reinforced spring and an undercutting width of 260 mm;

- section of SZ tines with an undercutting width of 260 mm, but with the bolt protection;

- NEW: SE tines section of the cultivator The tine has got dimensions 32x12 mm and is equipped with an additional 32x10 mm reinforcing spring;

3-row section of SE tines provides a full undercut with tines spacing of 320 mm and a graduation of 125 mm, while the undercutting width is much smaller than that of the SX tine and is 175 mm. Cultivator section with full undercutting minimises resistance when working with soil loosening.

|

| |

|

|

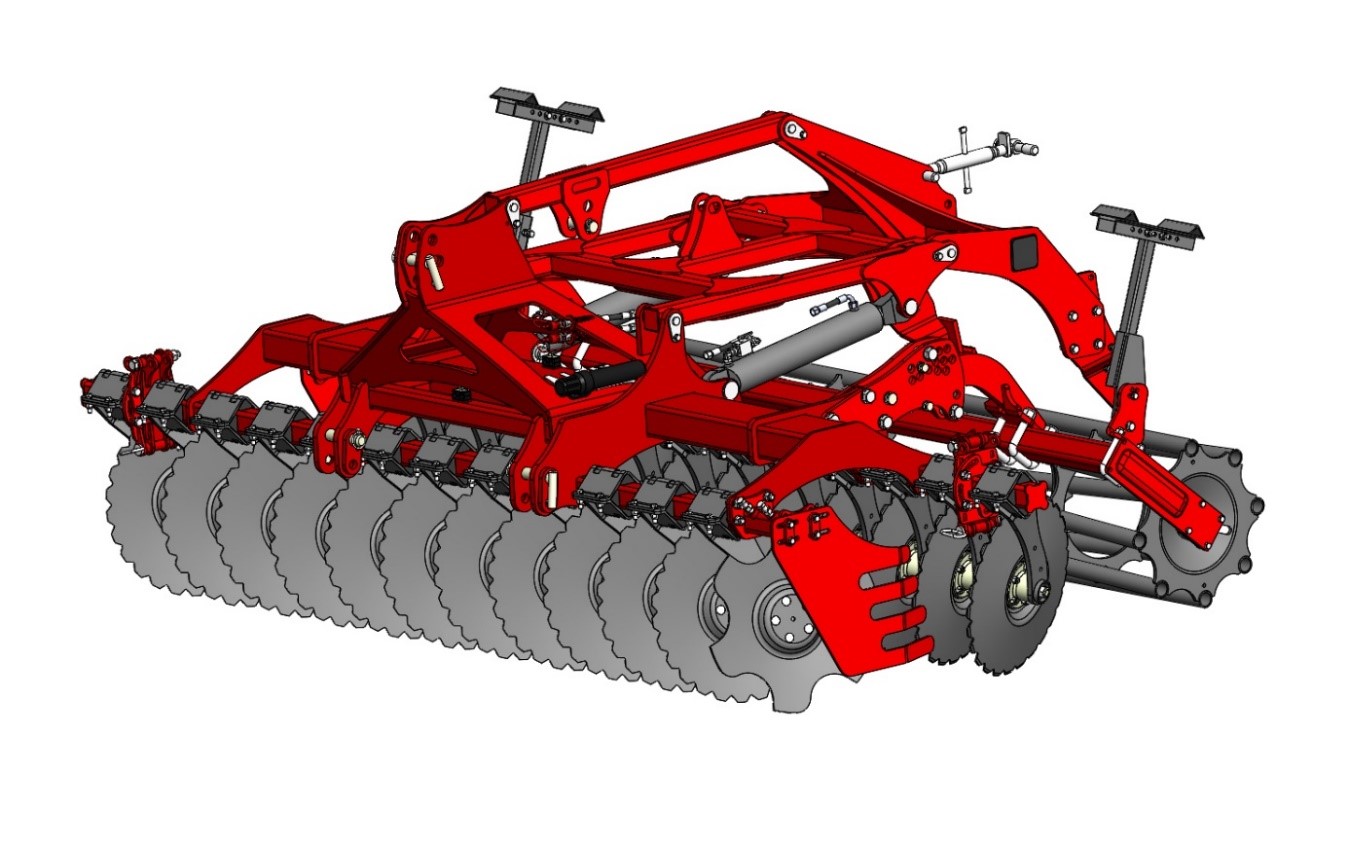

| 5. ARES L PLUS 560 |

| |

|

|

|

|

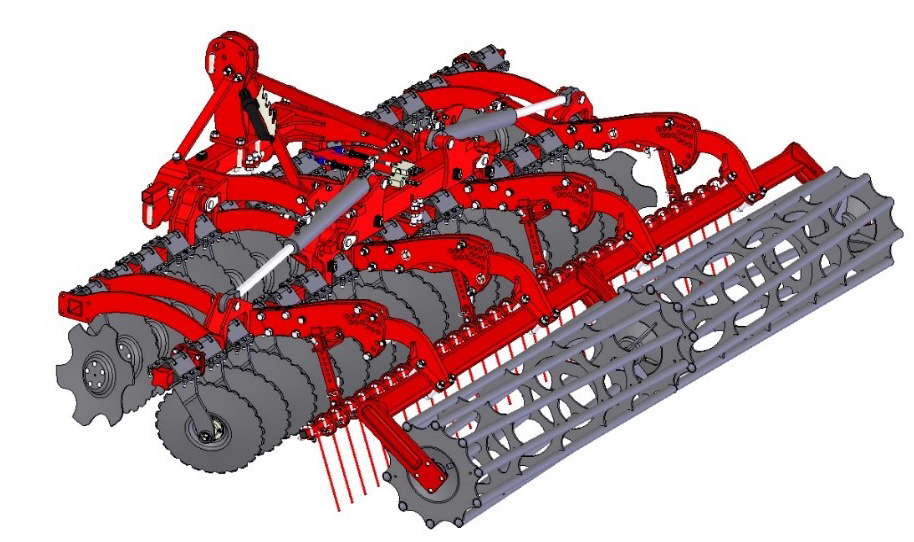

ARES L PLUS unit was created on the basis of the ARES L unit, which is well-known to UNIA customers. The implemented changes made it possible to meet the needs of our customers by introducing new construction and technological solutions.

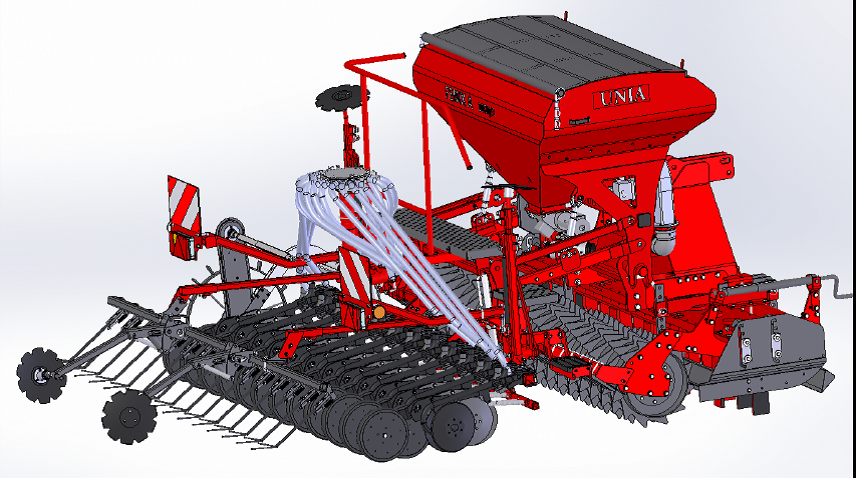

As the 560 description in the ARES L PLUS 560 model name suggests, this short disc cultivator is equipped with discs with a diameter of 560 mm and thickness of 4 mm, with a disc row spacing of 700 mm. The novelty is the replaceable maintenance-free bearing assemblies. This unit can be optionally equipped with a seeder coupler, seeder supports, side deflectors, and a Pipe roller with a diameter of 500 mm. At the exhibition this cultivator will be assembled with the seed drill forming a cultivating-and-seeding combination.

|

| |

|

|

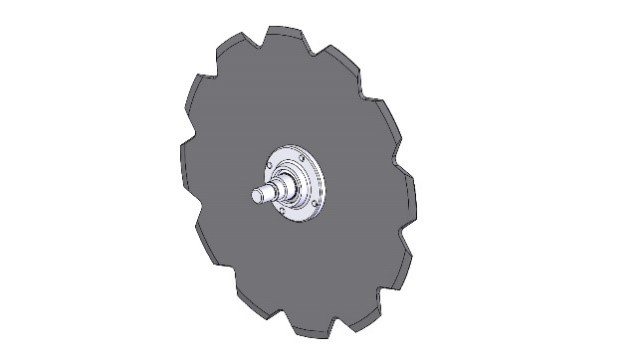

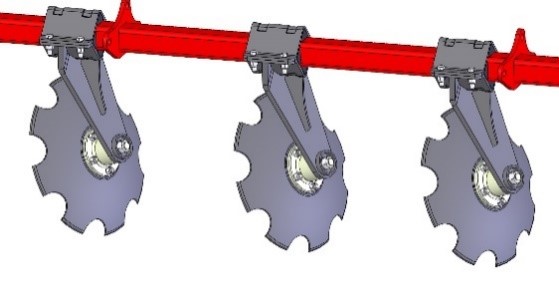

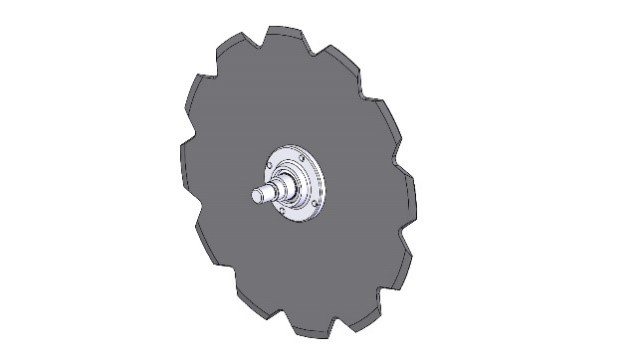

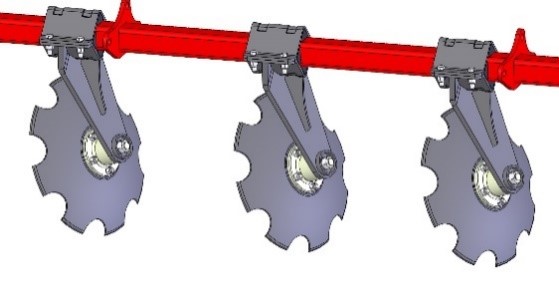

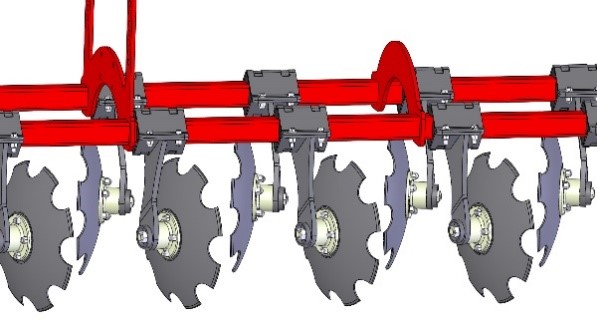

| 6. Maintenance-free bearing assemblies |

| |

|

|

|

|

|

| Maintenance-free hubs in disc coulters |

A single type A disc harrow with maintenance-free hubs |

A double-action B disc harrow with maintenance-free hubs |

| |

|

|

|

All models of bed-ploughs as well as reversible ploughs have got maintenance-free bearing assemblies instead of hubs with grease fittings. This improvement simplifies the daily operation of the machines. Maintenance free hubs were also implemented into the disc sections of the KOS, KOS PREMIUM, CROSS, CROSS HP and CROSS DRIVE cultivating units.

|

| |

|

|

| SOWING |

| |

|

|

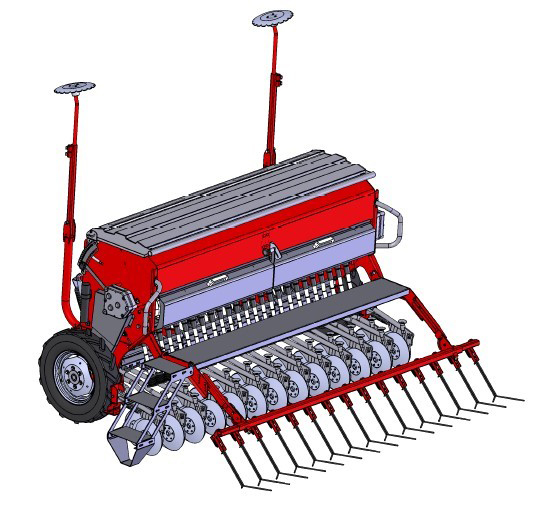

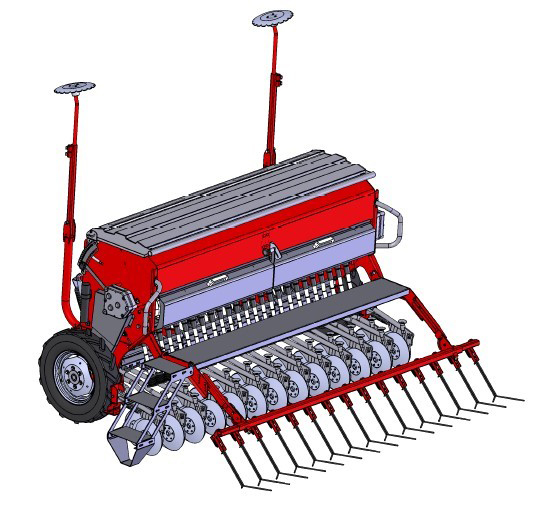

| 7. POLONEZ 550/3D DUPLO – new seeding apparatus |

| |

|

|

|

POLONEZ mechanical row seed drill line has been extended with the DUPLO version. In its machines, UNIA uses DUPLO description to name the simultaneous sowing of seeds and fertilizer. The DUPLO seed drill hopper is divided into the seed part and the fertilizer part in a 50/50 ration. The additional sowing devices are powered by a second gearbox and allow to spread up to 300 kg of fertilizer per hectare. The seeds and fertilizer are transported from the sowing devices to the special funnel which directs the seeds and fertilizer to one coulter via a telescopic hose. POLONEZ 550/3D DUPLO seed drills have got the alternating SHELL coulter, which can also be equipped with 300x50 mm ground-following wheel. |

| |

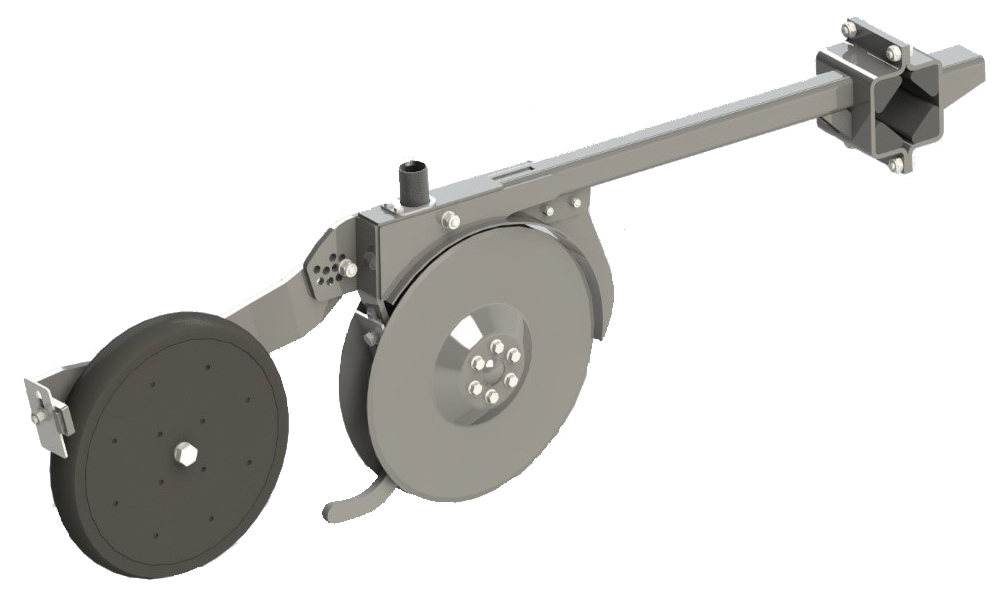

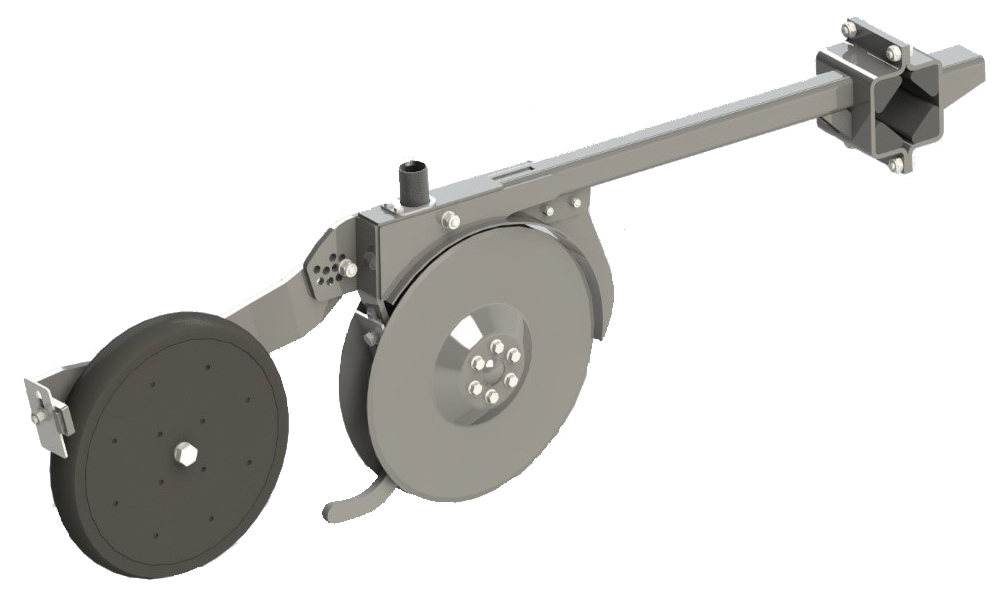

| 8. FS T DRIVE 1500/3 – new heavy coulters |

| |

|

One of the most popular UNIA combination seed drills has got a new V-Tech heavy coulter. Disc coulters with a diameter of 350 mm are set in a “V” arrangement on the durable maintenance-free bearing assemblies mounted on the inner side of discs. Four triangular rubber shock-absorbers, on which the coulters are mounted, provide 60 kg of clamping force on the soil. The 300x50 mm ground-following wheel with simple adjustment is used to keep working depth. New coulters are mounted with a spacing of 15 cm.

|

|

| |

|

|

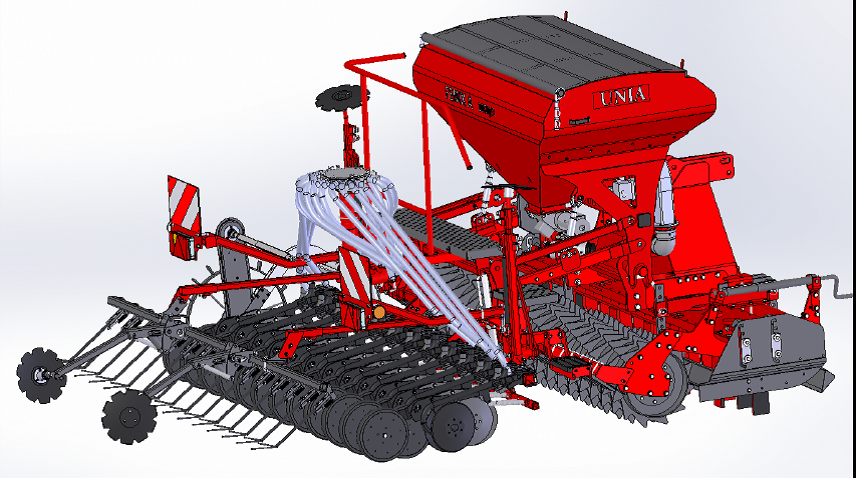

| 9. FENIX A 1000/3D |

| |

|

|

|

Mounted combination seed drill FENIX A 1000/3 is an alternative to the well-known FENIX A 700/3 unit. The working width of both machines is the same (3 metres), but the capacity of the seed hopper in the new unit is 300 l bigger (=1000 l). It is due to the fact, that the seed distributor was moved out of the seed hopper above the sowing coulters. The sowing system remains identical (universal sowing apparatus driven by the ground-following wheel takes the seeds, which are transported by the air stream first to the distributor and then to the coulters). FENIX A 1000/3 can optionally be equipped with an electric drive of the sowing apparatus. The working speed is read out by the radar and all sowing processes are monitored by the DRILL CONTROL computer of Müllerr Elektronik. In the new FENIX A 1000/3 unit the active harrow with 12 rotors and 285 mm long blades (FENIX A 700/3 has got 14 rotors and 250 mm long blades) is responsible for cultivation. The rotary harrow is therefore more robust and adapted to more difficult working conditions. In addition, a larger Packer roller with a diameter of 550 mm is installed behind it. In fact, it is a standard HERMES harrow that UNIA has had in its offer for several years. Assembling or disassembling of the seed drill takes very little time, which makes it possible to use the rotary harrow for working solo. |

| |

|

|

| FERTILIZATION |

| |

|

|

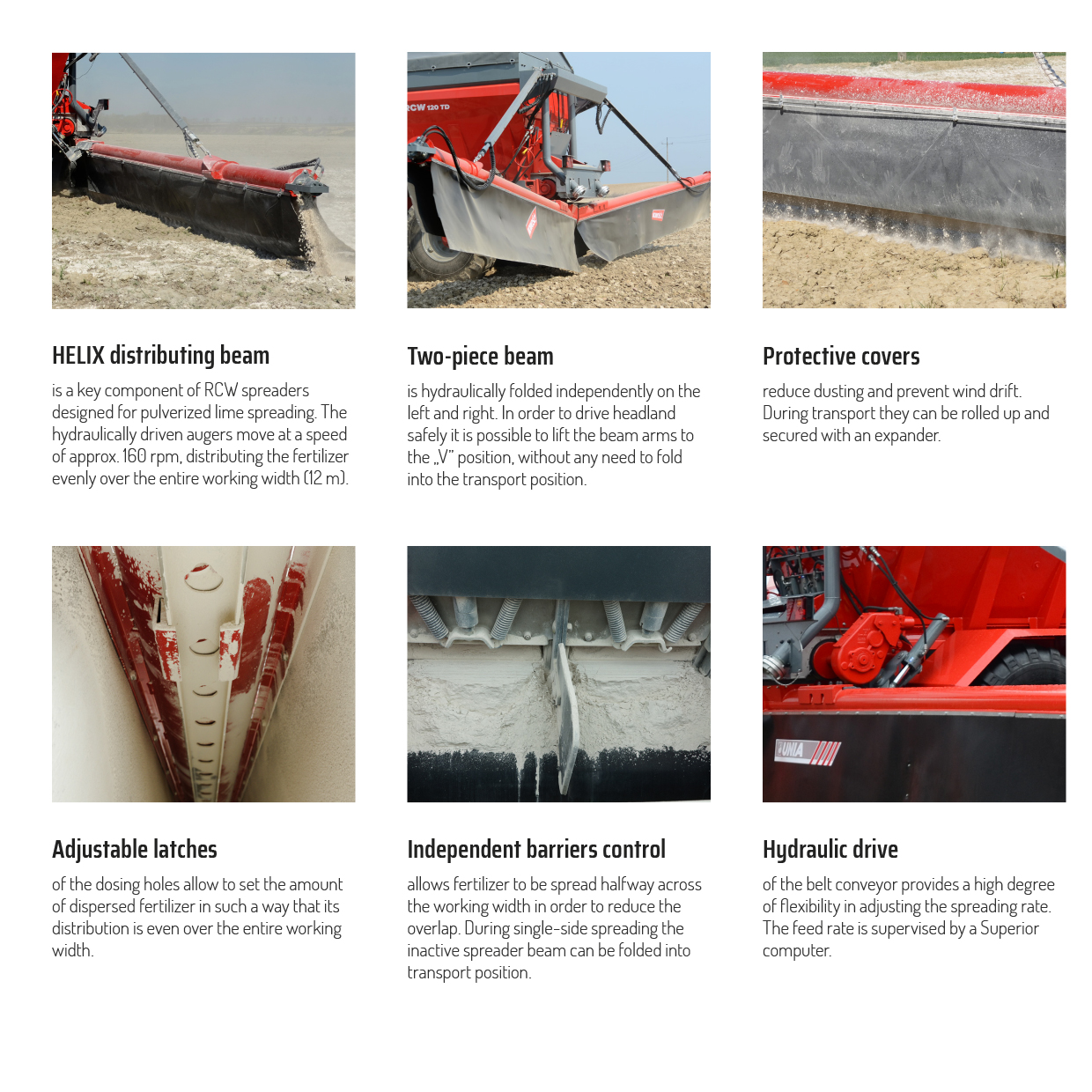

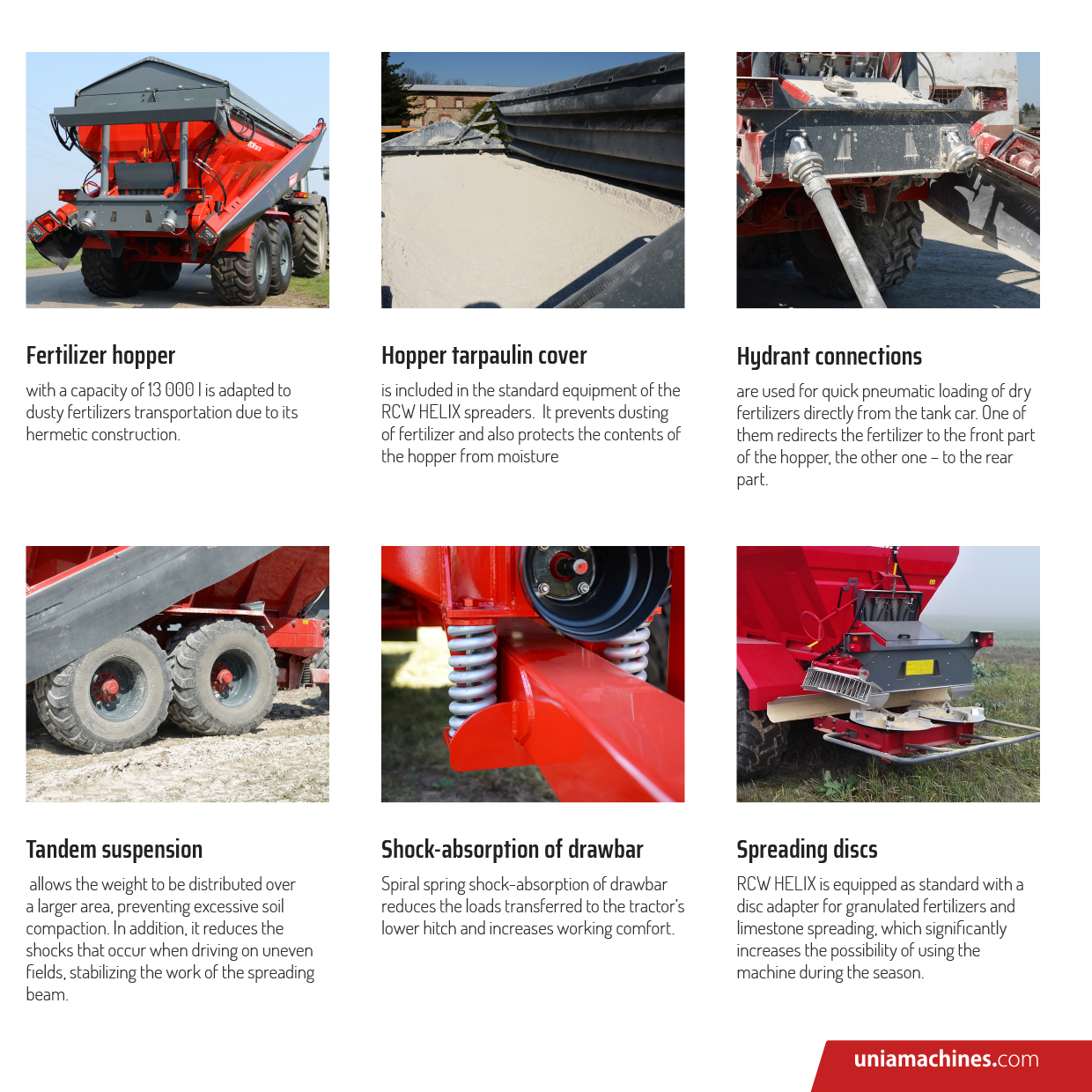

10. RCW 120/120TD with a bar for the distribution of powdered fertilizers

|

| |

|

|

| RCW 120 TD spreader is a universal machine for the fertilizers and lime spreading. Hopper capacity is 12 000 l and is divided by the capacity of the vehicles transporting the lime to the field. The machine has got a sprung tandem chassis system based on 600/55 R22.5 wheels. Two solid springs are provided between the drawbar and a spreader frame to cushion the hitch. As standard, the RCW 120TD has got hydraulic drive of the conveyor and mechanical drive from PTO shaft of spreading discs. The spreader can also be equipped with a drive of conveyor from the star wheel. Optionally, all functions of the spreader can be controlled via the SUPERIOR computer. The working width of the machine depends on the spreading material. For fertilizers it can be up to 48 metres, while for lime it is from 8 to 16 metres. |

|

|

In order to maintain the highest precision and reduce losses during the distribution of powdered fertilizers, the manufacturer offers a distribution bar. The bar width for the RCW 120TD is 12 metres. Augers conveyors with a diameter of 150 mm are used to distribute material over the entire width of the bar. The bar is powered by two hydraulic engines. It is hydraulically folded from the tractor’s cabin to the transport position. The partial folding of the bar makes it easier to turn at the end of the field, without the risk of catching the spreader on the bumps or obstacles. The hopper is filled up pneumatically via a pipe directed straight to the hopper. The mandatory element in this set is hopper tarpaulin cover, which seals the entire system during loading and work.

Liming in this way is cheap and the farmer does not have to worry that the purchased lime will land on his neighbour’s field. The spreading is very precise due to the lack of wind drift. The larger the farm acreage, the more profitable it is to buy a spreader of this type, especially as fertilizer companies right now transport lime via the tanker directly to the field. The benefits of liming are measurable. Harvest residues decompose more quickly, water retention in the soil increases, and the soil structure is being improved. Spreading of lime is an innovative method, simple and economical.

|

| |

| 11. TYTAN – shredding disc adapter |

| |

|

|

|

TYTAN spreaders can be equipped with a disc adapter with shredding mechanism. It is used to spread rotten manure (without fresh straw) as well as lime, sludge, compost or peat. The high degree of grinding ensures that the material is precisely spread and quickly degraded in the soil. Working width of this adapter is from 12 to 20 m. |

| |

|

| 12. Superior computer in spreaders |

|

| |

|

SUPERIOR computer is well-known to Unia machines users. This highly advances computer is now applied in manure spreaders. It has got many functions and a large colour display.

Superior computer functions:

- deflectors, adapter covers and dosing gate service

- control of adapter cover opening (protection against protrusion when the cover is closed)

- protrusion speed regulation

- working speed counter

- indicator of rotation speed of distribution discs

- efficacy measurement

- working time counter

- emergencies information

Superior computer advantages:

- a 5.7” colour touch-screen display

- illuminated buttons (for night work)

- USB port for data transfer

- joystick for comfortable work

- touchpad for easy data entry

- controllability of other Unia machines (e.g. baler, seed drill, fertilizer spreader)

|

|

| |

|

| TRANSPORT |

| |

|

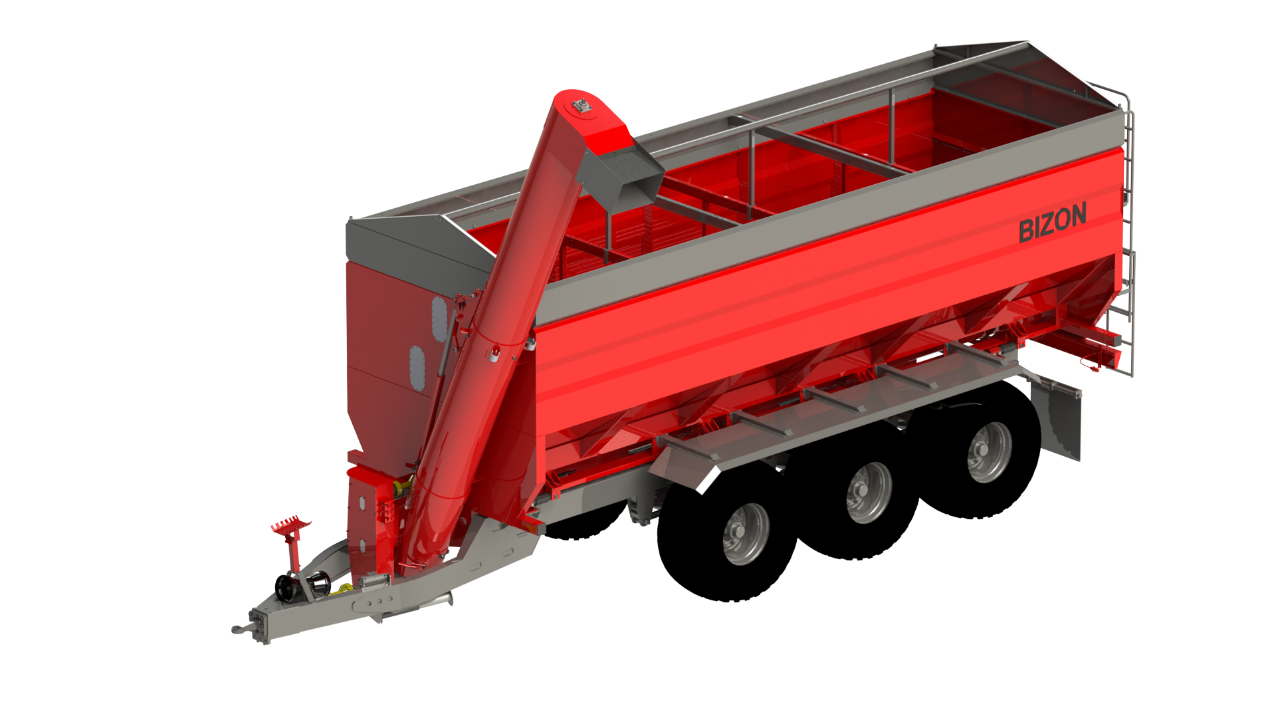

| 13. BIZON 36 |

|

| |

|

|

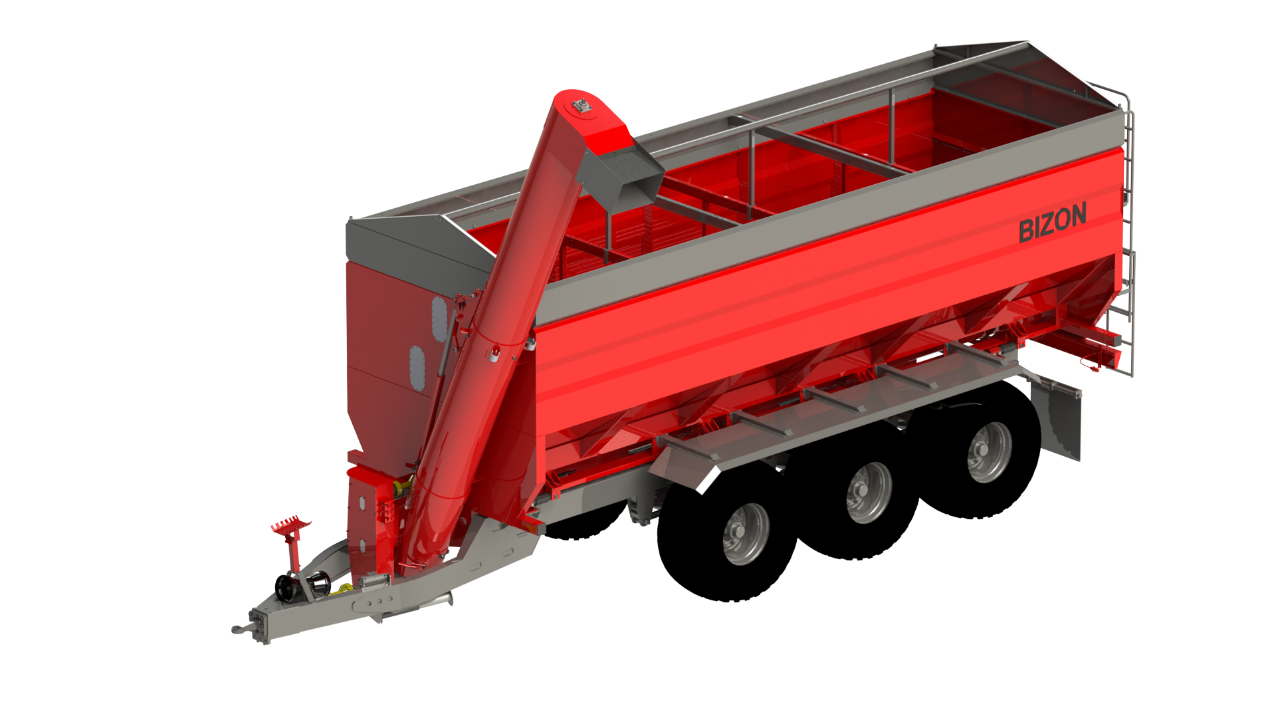

New BIZON 36 chaser bin designed to transport crops from the harvester to lorry trailer can save up to 30% of the harvester operation time. In addition, the electronic weighing system of this huge trailer allows for the recording of the transported seeds with an accuracy of 20 kg. An additional printer allows to record the result on a paper tape. Trailer's capacity is 38 m3. However, do not exceed the permissible total weight of 33 t on the road (traffic regulations) and 36 t on the field. The chaser bin is 2.9 m wide and 7.25 m long. It can be used to transport such materials as crops, corn, rape, sunflower seeds or granular fertilizers. The hopper is welded and mounted on the bottom frame with the use of weight sensors.

|

|

Two auger conveyors are mounted in the bottom of the hopper to transport the seeds. The augers have a variable stroke which prevents the material from clogging up during unloading and enables its even transport from the rear part to the discharge pipe with a vertical auger, which is powered directly from the tractor's PTO shaft by an intersecting axis gear. However, the horizontal auger located at the bottom is powered by the hydraulic transmission. The discharge pipe is folded and controlled hydraulically. During discharge it reaches a height of 4.7 m and is ended with a jet for directing the discharged material. This element can be set at different angles, which allows the precise transportation of crops. What is more, this system allows for lossless handling of different seeds even during the strong wind conditions. The discharge pipe diameter is 500 mm. Unloading efficiency is up to 500 t/h.

BIZON 36 can be equipped with a folded hopper tarpaulin cover that protects the cargo from rain. Two big inspection windows located on the front of the hopper give a clear view of the interior. The trailer has a tridem chassis system, with passive torsion of front and rear axis wheels. Wheels dimensions are 700/50×26.5. Trailer's speed limit is 40 km/h. BIZON 36 is designed to be aggregated with tractors with low hitch of 280 HP and more.

BIZON 36 is a novelty of UNIA brand presented for the first time at the Agro-Show 2018 trade fair.

|

| |

|

|

| PROTECTION |

| |

|

|

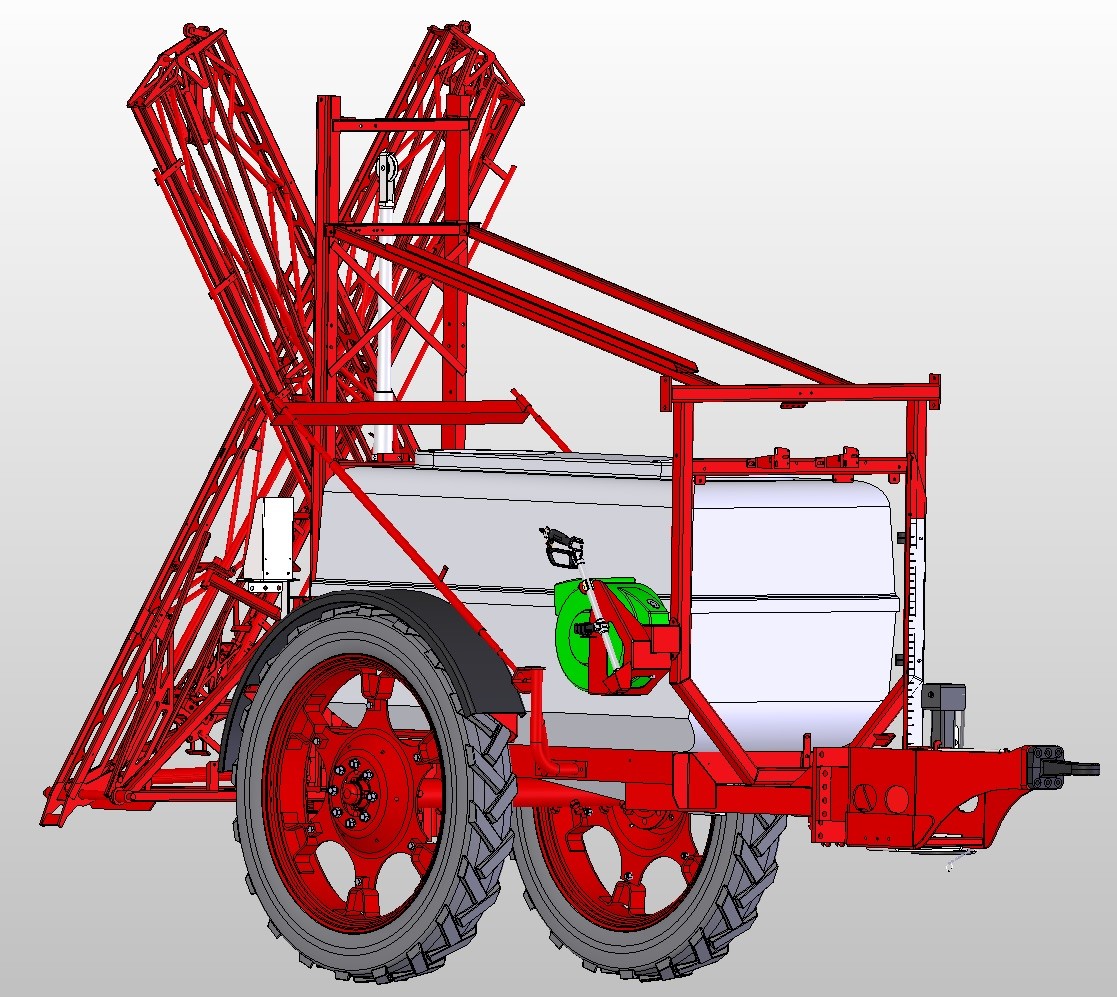

| 14. PILMET 1618 – new model of sprayer |

| |

|

|

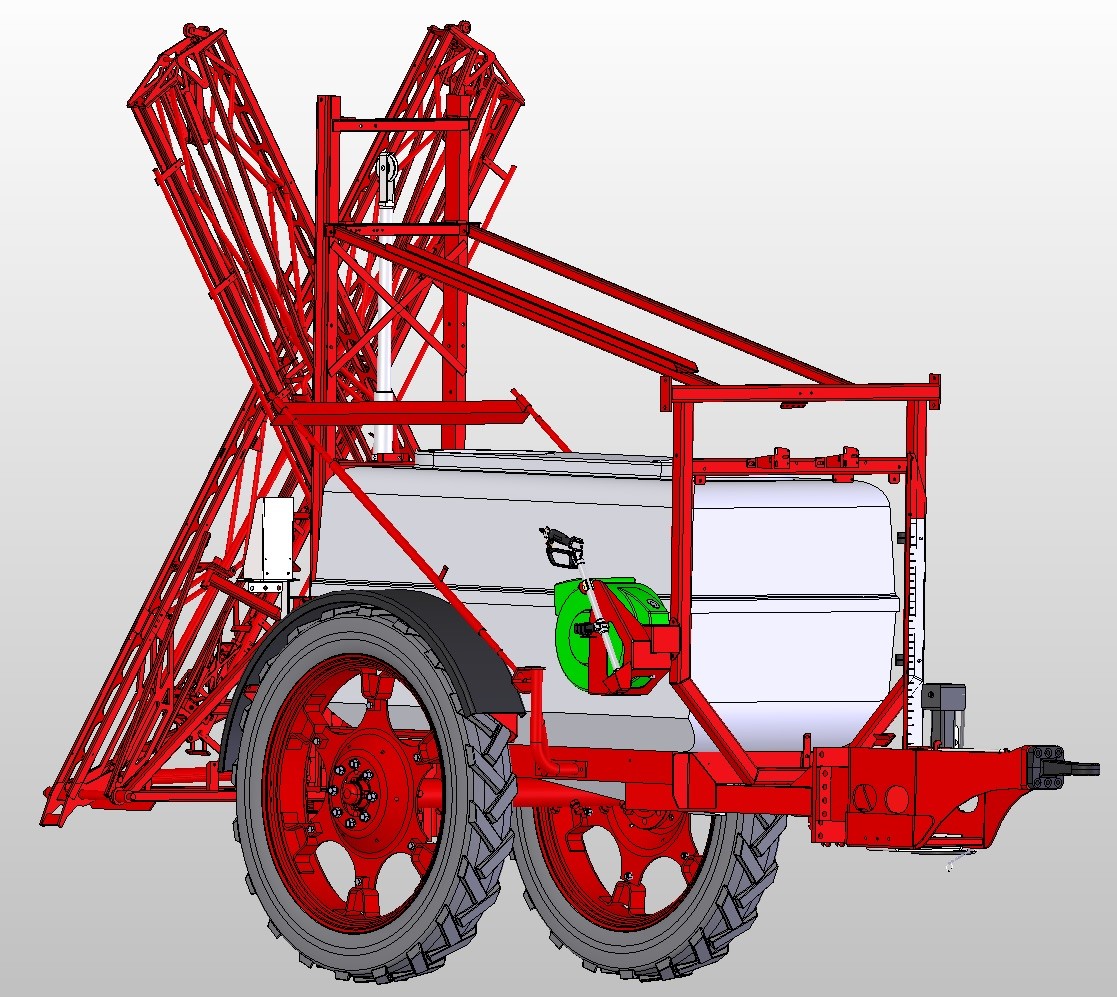

UNIA–Pilmet sprayers are the results of more than 65 years of experience in manufacturing plant protection machines for modern agriculture. Modern, yet simple solutions, efficient and durable fluid systems, lasting membrane/piston pumps, and stable field beams ensure precise application of the spraying fluid and maximum efficiency during the operation.

The PILMET 1618 is another new model that expands the line of UNIA sprayers. The new sprayer will have a hopper capacity from 1 200 to 1 600 litres on an axle with 9.5 to 36” wheels. Their spacing can be easily adjusted from 1.35 to 1.8 m. The axle may be equipped with an air brake system. Width of the field beam is 15 and 18 m ( which can be reduced to 15 metres ) .

Fluid system is powered by the membrane/piston ZETA 170 pump of nominal efficacy of 170 l/min. Sprayer tank is made of polyester. There is a clean water tank in the hopper, which constitutes 10% of the hopper capacity. There are two breakwaters inside the hopper which damp the fluid movements during the transport of the sprayer. |

|

The field beam in X arrangement is lifted and folded hydraulically using two cylinders with inclination cylinder and multi-position bodies mounted on the acid-resistant steel pipes. The advantage of this beam system is the possibility to lift each element vertically, which makes it very easy to avoid obstacles on the field, such as posts or trees, thanks to the fact that when the obstacle is reached, there is no need to turn the sprayer back - one only has to lift the beam. The working width of the field beams is 15 m and 18 m with a possibility of reduction to 15 m. As standard, the field beam is divided into 5 spraying sections with the possibility of extension to 7 sections. After the extension to 7 sections, the boom reduction from 18 to 15 metres will mean the closure of the outer sections. The field beam is equipped with pendulous stabilisation system with shock absorption.

The sprayer can be additionally equipped with the SPRAY computer, a fully automatic unit for operating the sprayer, with a fully integrated control panel. The central, sectional and fluid control valves can be operated from the tractor's cabin. A maximum of 9 sections can be controlled. The computer allows the beam to be folded out and levelled. The operator determines the spraying rate and, with the aid of a flow meter and speed sensor, the computer maintains the spray rate per hectare regardless of the drive speed. The sprayer is also equipped with the ZTS constant pressure valve.

The sprayer may be also equipped with the lateral water diluter, which improves the dilution of plant protection agents, and an independent beam to facilitate bypassing the slopes on the field beam path. |

| |

|

|

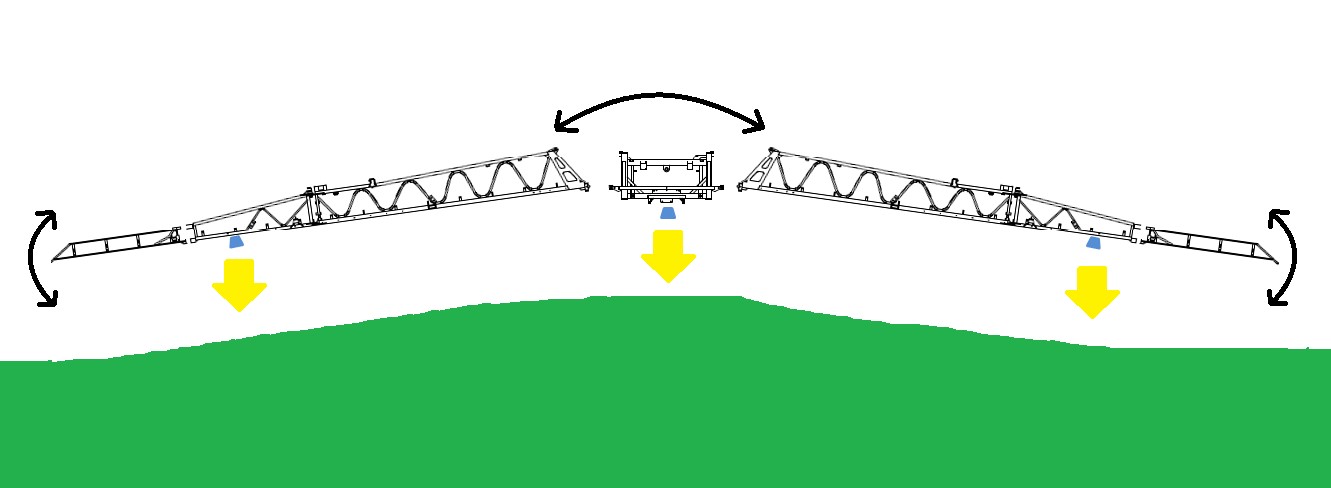

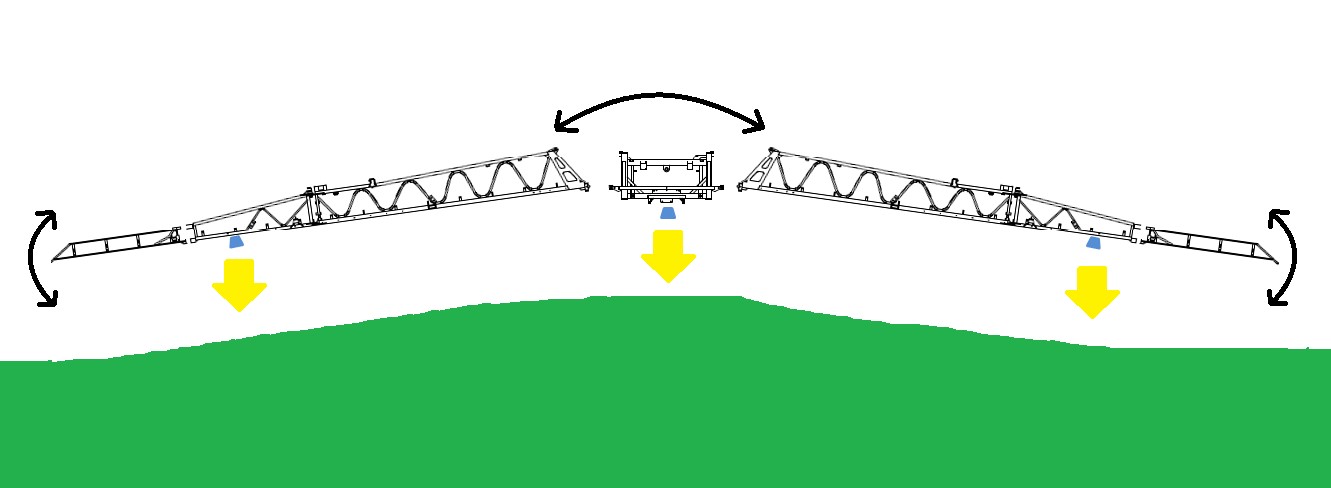

15. V-system – variable geometry of the beam

|

| |

|

|

|

| |

|

|

| The variable geometry of the beam controlled by three DYSTANS CONTROL II ultrasonic sensors increases the precision and efficiency of the application by automatically adapting the height and the angle of the beam adjusting them to the terrain. The system corrects the accuracy and the evenness of the spraying while reducing drift. Simultaneous bending of the boom arms with hydraulic cylinders combined with the possibility to rotate the central part makes a perfect adjustment of working field while operating on the hilly land. The basic version of the system, available until now, operated on two sensors and its beam could be inclined only to its entire working width. |

| |

|

|

|